Fabrication and Diagnostics of Automotive Batteries

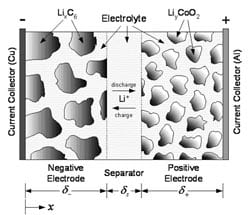

Researchers at the Electrochemical Engine Center (ECEC) develop manufacturing and diagnostic techniques for automotive batteries such as Li-ion, Ni-MH, and lead-acid. Current interests include low-cost anode and cathode materials, cycle life, thermal safety, and low-temperature performance of Li-ion batteries.

Dynamics and Modeling of Automotive Batteries

At the ECEC, we have been working on electrochemical-thermal coupled modeling of lead-acid, Ni-MH, and Li-ion batteries for electric cars since 1994. At the pore scale, we develop direct numerical simulation tools to engineer interfacial structures of electrodes. At the cell level, we explore the electrochemical and thermal interactions in hybrid electric vehicle applications. At the pack level, we study cell imbalance, its root causes, and mitigation techniques.

Modeling and Simulation of Electric Vehicle Batteries

Investigators: C. Y. Wang, Wen-Bin Gu, Xiaoou Chen, and Shimei Li. Sponsor: U. S. Defense Advanced Research Projects Agency.

Understanding the electrochemical and physical processes occurring inside battery cells is a key to:

- predicting the charge and discharge performance of EV batteries;

- identifying various mechanisms limiting battery performance; and

- developing optimal charge algorithms.

This research project investigates the complicated chemical and physical phenomena that govern the battery performance, such as electrochemical kinetics, mass transport in porous electrodes and free electrolyte, fluid flow, and thermal effects. A comprehensive model is being developed to incorporate all these phenomena, and the resulting model equations are solved using computational fluid dynamics (CFD) techniques.

Simulation results will provide the detailed information of concentration and current distributions, and charge and discharge curves. These results would yield significant insight into responses of battery to various charge and discharge modes, and thus help to design optimal charge algorithms. In addition, the developed numerical simulator for battery performance can be readily integrated into the vehicle simulation.

Rapid Charging of Advanced Batteries

Investigators: C. Y. Wang and Wen-Bin Gu. Sponsor: U. S. Defense Advanced Research Projects Agency.

This project uses CFD-based battery models and codes to develop pulse charge algorithms for advanced batteries such as valve-regulated Lead-Acid, Ni-Cd, Ni-MH, and Lithium-Ion batteries.

CFD Modeling of Ni-H2 Batteries with Convection

Investigators: C. Y. Wang, Rebecca Cullion, and W. B. Gu. Sponsor: NASA, Jet Propulsion Laboratory.

The objective of this project is to extend an existing NASA/JPL cell model to fully account for coupled thermal and electrochemical behaviors of aerospace Ni-H2 batteries. The extended model is multi-dimensional and includes not only complex electrochemical reactions, gas evolution and non-isothermality but also gas dynamics within the entire battery vessel. Comprehensive computer simulation is performed using a computational fluid dynamics technique adapted to electrochemical systems. The CFD model can be used for design and optimization of aerospace Ni-H2 batteries.

Battery Cycle Life Prediction

Investigators: C. Y. Wang, Guoquing Wang, and Y. Pan. Sponsors: U. S. Department of Transportation Advanced Vehicle Program and Hawaii Electric Vehicle Demonstration Program (HEVDP).

The objective of this project is to develop a reliable and fast predictive tool for battery cycle life through a full understanding and characterization of the nature of primary deterioration and failure processes in Valve-Regulated Lead Acid (VRLA), Nickel Metal Hydride (Ni-MH) and Lithium-Ion (Li-Ion) batteries, respectively. The project will use the integrated experimentation and computational fluid dynamics (CFD) approach to develop a mathematical model describing these deterioration and failure processes as they affect the life and long-term performance of the batteries. The project is a collaborative effort with Dr. B.Y. Liaw at the Hawaii Natural Energy Institute of University of Hawaii.

Integrated Simulation and Testing System for Electric Vehicle Batteries

Sponsors: U. S. Department of Transportation Advanced Vehicle Program through the Mid-Atlantic Regional Consortium for Advanced Vehicles (MARCAV), Arbin Instruments.

This project is to develop and build a first battery testing/analysis system with both simulation and testing capabilities integrated seamlessly in a single product. The simulation technology is based on the computational fluid dynamics (CFD) technique previously developed with Defense Advanced Research Projects Agency (DARPA) support.